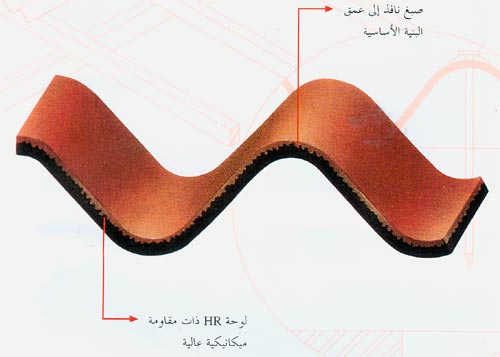

The main component of

Onduline Roofing System is the Onduline HR roofing sheet. The

Onduline HR (High resistance) sheets are manufactured using a

sheet of organic fibre which is being impregnated with bitumen

and pre-pigmented with a special resin. The paint impregnated

into the sheet together with resin by employing a special

technique ensure the Onduline HR colors to retain in their

original characteristics even under extremely severe conditions.

In fact, Onduline HR is a perfectly watertight, absolutely

stainless, maintenance-free and ecological product which never

gets cracked due to its flexible structure, does not become

moldy, does not contain asbestos, is resistant to UV rays and is

not affected by the airborne chemical and biological substances.

High Quality Production

Onduline Manufacturing

plant is

built in Western Turkey. The plant employs special technologies

developed by Onduline Group to produce the Onduline HR roofing

and wall cladding sheets, and also the Isolin-Rufpline. S sheets

used under tiles and Bituline waterproofing membranes. The

Onduline Group and Onduline Avrasya have been rewarded with

various certificates and awards by virtue of all their

manufacturing processes being designed according to ecological

technologies and modern principles.

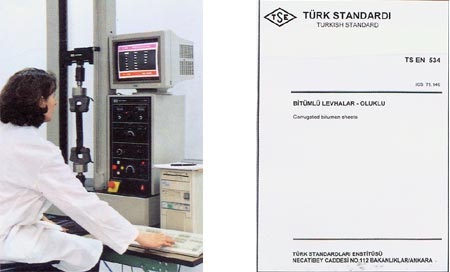

Onduline HR

sheets are

manufactured and tested according to the EN 534 standard adopted

by CEN (European Committee for Standardization) to the “Category

A” specifications indicated for “ superior quality” therein.

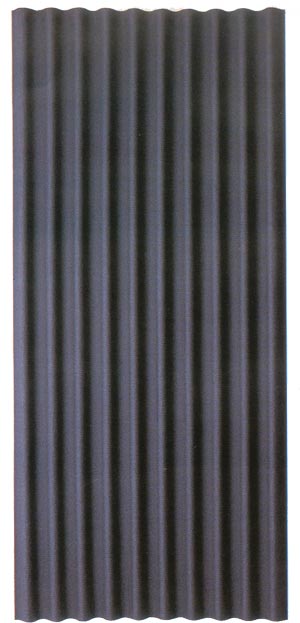

Onduline HR

Roofing Sheet

Width

: 95 cm

Length : 200 cm

Covered roof per sheet :1.59 sqm/sheet

Weight : m 6.5 kg/ sheet

Corrugation height : 4 cm

Number

of corrugations : 10

corrugations/sheet

Packing : 300 and/or 350 sheets/pallet

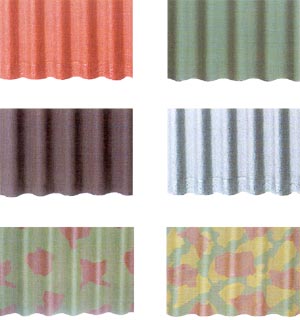

Onduline HR

sheet

and ridges are available in standard colors of black, The color

of choice is applicable to the outer surface

The color of choice

in Onduline HR 2 type sheets is applicable to both sides.

On

request sheets may also be manufactured in also be manufactured

in special colors of brown, aluminum, natural and camouflage, on

request.

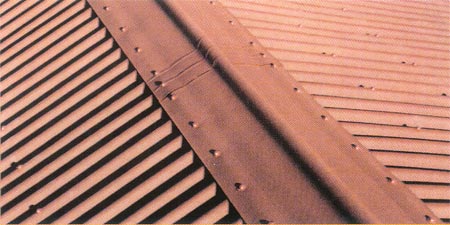

Onduline HR Ridge

Width : 48.5 cm

Length : 200 cm

Quantity : 0.54 unit/meter

Weight : 2.75 kg/unit

Packing : 25 units/ pallet

Technical

Characteristics

Waterproof

Absolutely waterproof under all climatic conditions.

Light weight

With

an overall weight of 4 kg/sqm, it is highly advantageous with

regard to easy application and earthquake safety.

Resistance to UV Rays

No

surface deformation takes place under effects of ultravionlet

rays.

Bending under Vertical

Load

Capable of carrying homogenously distributed load of up to 350kg

per square meter at a 45 cm purlin distance within the maximum

deflection tolerance of 1/200

Resistance to High and

Low Temperature

No

visible changes occur in the material to a temperature range

between -35 to+105 degrees Celsius. No cracks or scaling

actually take place. The change in dimension due to temperature

difference of 50° c is less than or equal to 0.1%

Thermal Conductivity

The

thermal conductivity value of Onduline HR is l=0.105 kcal/mh°c

Sound Absorbency

The

sound absorbency value is 40 dB on the average.

Biological

Characteristics

Ondulin HR sheets do not decompose nor detoriate by adverse

effects of any biological factors such as mold fungi.

Chemical characteristics

Various salts, acids and alkalis do not cause any changes in the

performance of Onduline HR.

No Asbestos

Onduline HR sheets do not contain asbestos.

Onduline HR was tested and demonstrated to meet to all required

quality standards, through a number of tests conducted at

various laboratories of our country.

Below

is list of the tests conducted for this purpose:

Appearance, shape and dimension standards test,

Hardness

Impact

Resistance

Collapse under load

Bending

Aging

Accelerated Climatic Conditions

Thermal Expansion

Frost

Resistance to High and Low Temperatures

Inflammation

Water

Absorption

Waterproofing

Weather-proofing

Resistance against chemicals and salts

Soluble bituminous material

All

the above listed tests were conducted at the following

laboratories :

TSE

Chemistry and Materials laboratory, Ankara

Building Materials Testing laboratory, Dept. of civil Eng. METU,

Ankara

General Directorate of Building Materials, Ministry of Public

Works and Settlement, Ankara.

Materials Laboratory, Dept. of Civil Eng., ITU, Isanbul

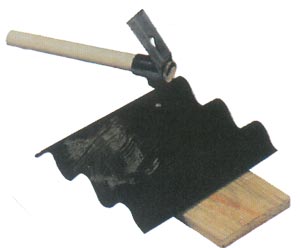

Application Guidelines

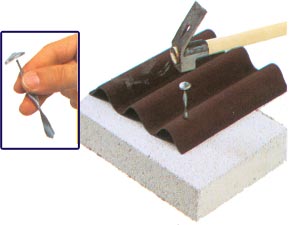

1

Onduline HR 95/200

2

Onduline HR ridge 48.5x200

3

Wooden batten

4

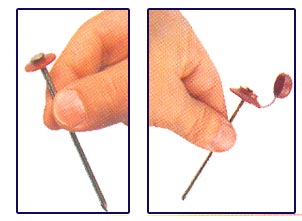

Galvanized nail with plastic washer 1=8cm

5

Wooden rafter

1

Onduline HR 95/200

2

Galvanized nail with plastic washer 1=8cm

3

Wooden purlin

1

Onduline HR 95/200

2

Onduline HR ridge 48.5x200

8/5

3 Wooden purlin

4

Galvanized nail with plastic washer 1=8cm

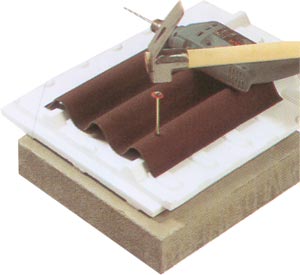

1

Onduline HR 95/200

2

Onduline HR ridge 48.5x200

3

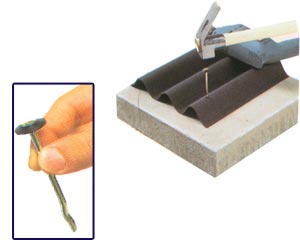

Onduline concrete nail 1=7cm

4

Reinforced concrete roofing

1

Onduline HR 95/200

2

"GASBETON" roof panel

3

Special screw nail 1=10cm

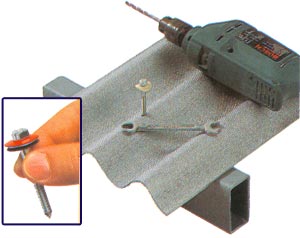

1

Onduline HR 95/200

2

Steel purlin 40x60

3 Hook

1=18cm

4 self

drilling metal screw

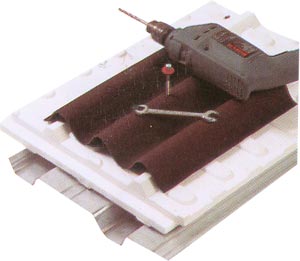

1

Onduline HR 95/200

2

Onduline HR ridge 48.5x200

3 ESP

or XPS

4

Onduline concrete nail 1=10cm

5

Reinforced concrete roofing

1 Onduline HR 95/200

2 ESP

or XPS

3 Wooden batten

4 Galvanized nail with plastic washer 1=10cm

5

Wooden rafter

1 Onduline HR 95/200

2 ESP

or XPS

3

0.65mm trapezoidal metal sheet 27/200

4 Self

drilling metal screw

5 Steel purlin