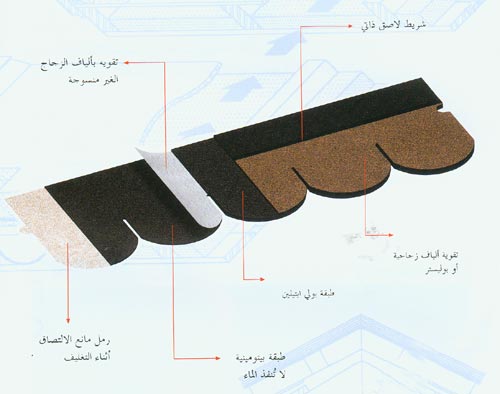

Bardoline system is singil used for

covering roofs and it is made of oxidized Bitomine With high

technology strengthened with unwoven glass fibers covered with

variable kinds of crashed stone (Granulite). These singil are

typical for roof with slop 30% or more. And if necessity they

can cover roofs with less slop or vertical faces.

Advantages:

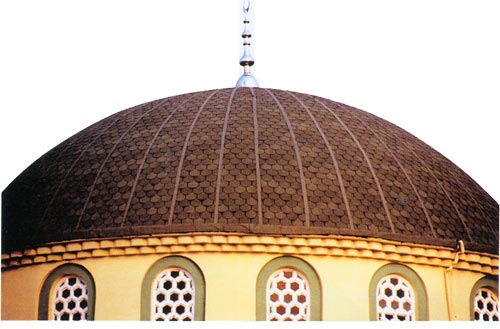

It is proper to any kind of roofs which

are covered with other materials, or those with irregular shapes

to be moderated to be proper for slop roofs like domes or

basements.

It has beauty value because of

intersected view and attractive colors.

It is so easy to be applied

No penetrating of water, and prevents

cracks caused by variable temperature because of divided and

flexible structure.

Easily to be stepped on

No need for extra materials for details

like back board and drainage cannels, walls ends, and Chimneys

so roof shape can have completed only with one material.

It is a light material because it

weighs only 10kg/m². And it gives the roof shape light weight.

Bardoline System is easy to be executed

on all kinds of buildings, easy to be applied, no penetrating of

water, products with create light and beautiful roofs

Shapes and Standard Specifications:

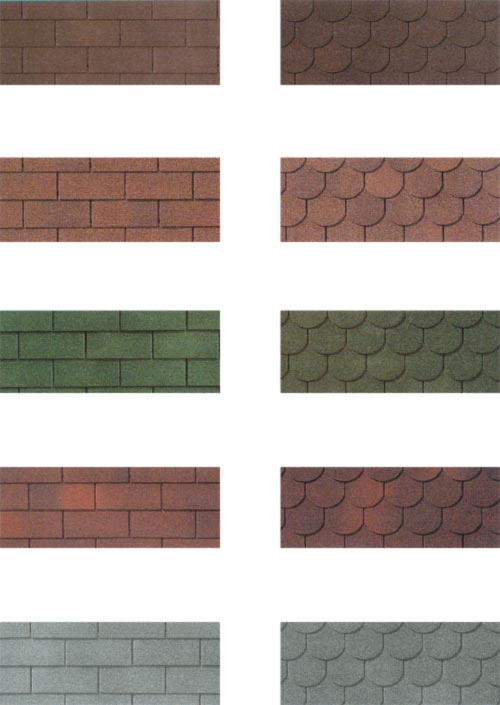

Singil can be formed with three shapes(

Bardoline S, Bardoline and Bardco).

Bardoline S, Bardoline: equivalent to

standards approved in European Union and they are produced and

tested according to the standard TSE 544 approved by Turkish

company for standards. They are singil considered as first class

according to the Turkish company which are suitable for all

region climates all over Europe.

Bardoline S: It is not only a approved

according to the standard specifications TSEN, but also it

comes over it because of qualities. As it has fibers with high

density with great ability to face mechanical forces with high

qualification . Also it can be applied even if weather is cloudy

or cold. And with self adhesive tap it doesn’t need heating for

welding . So that it supplies speed and easy execution. even if

there is a height wind, Bardoline S can be applied safely

without any dangers.

Bardco: It is produced according to

American standard ASTM. It is economical, with high resistance,

and provides cheaper possibility to cover roofs.

The Base( under ground)

:

singil of Bardoline line type can be

applied by hammering or sticking . If the method of hammering is

used, we should use specialized galvanized Bardoline with wide

head. The wooden underground base is used to be dovetailed with

smooth level . And we can use tight wooden boards or countrblack

or OSB.

If we want to cover concrete roofs

straightly with Bardoline ,sticking method on the surface of

concert should be applied, by flame machine and with one layer

of Bituminuma material strengthened with fibers

In these applications using the

Bituminuma material of kind Bituline PG300. is recommended. The

same sticking method is applied for wooden roofs with slight

slope.

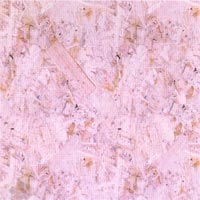

Onduplak : with high quality OSB3

OSB(Oriented strand Board) : is a kind

of modern wooden boards used for covering roofs. The kind OSB

recommended in wet places which never have any change of shape

is called OSB3.

Onduplak board with high technology

OSB3 is produced also in West Europe and have the document EN300

of European standard of quality. Onduplak is good to cover the

wooden roofs and typical as basic material for the underground

of singil

Technical Specifications:

|

Width |

1220mm |

|

Length |

2440mm |

|

Thickness |

9mm-11mm |

|

Density |

620/640kgm/m³ |

|

Accepted error of length |

+0/-2mm |

|

Accepted error of thickness |

+ - 0.8mm |

|

Slope from the vertical angle |

3mm |

|

Directness |

0.6mm/m |

|

Length stretch(85-65% extra

humidity) |

0.15% |

On installation it is important to take

into consideration to equal the short edge of the face to the

extensors, also 3mm space should be left between boards classes

for extension. The conjunction point of followed board should be

on the extensors In case of any prevention of extension of wood

which covers the roof, a space with 2mm for each meter and 10mm

space for the whole extension.

Boards with 11mm thickness should be

applied on roofs which bear normal weight . proper space between

extensors is 2440mm/5= 488mm.

Boards can be fixed by nails 3mm

diameter and 5 cm length. The distance between the point of

hammering and board edge is 6mm at least.

Base of

Application:

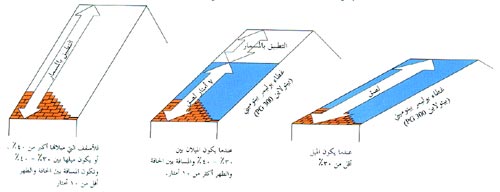

1 Slope : On

applying slope of nails should be 30% at least, but when the

roof slop is less than approved, Polymer Bituminuma cover with

strengthened fibers with 3mm thickness should be applied by

flame machine.

Singil shall be

applied on roofs by sticking nails shouldn’t be used if slope is

between 30 and 40%, or the roof edge is over 10m. Sticking

method shall be applied on 7m as from the edge. Bituline PG 300

Bituminuma which is produced according to TSE standard ( Turkish

Company for standards) is the best method to apply the singil on

roofs.

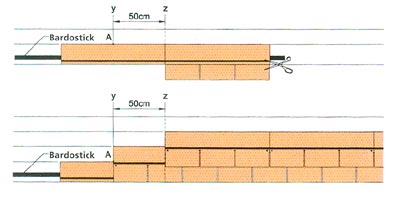

2 Fixing and

Impacting: Bardostick tap shall be applied on the end of the

edge . Bardoline should be cut and sticker on the edge lime with

Bardostick to form the ground of first class of singil. And when

the second class impacted, the conjunctions should be neutered

to put some of them in the middle of notches on the board s

edge to facilitate and help to moderate the neutering and equal

spaces between classes.

Singil should be

fixed on the wooden structure by galvanized Bardoline nails with

wide head when slope of the roof is more than 100% and on

vertical faces, number of nails should be increased to 50%.

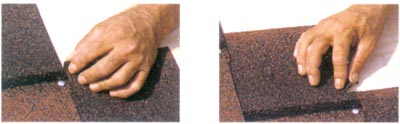

In hot and sun

shine, Bardoline and Bardco singil can stick to each others be

cause of their self weight But if the weather is cold and

cloudy, we should stick places of installation by heating them

throughout flame machine . and impacting them one over the

other.

Environment

effects, dirtiness, dust and humidity affect the sticking

process, so we shouldn’t apply the sticking before taking these

effects into consideration and checking them well.

Bardolin special

sticking tap facilitates the self sticking in temperature over

than 10°c During the application Boly Ethelen layer should be

removed and singil shouldn’t be left under strong sun shin for

along period before removing Boly Ethelen layer.

3 Ventilation :

Roof which are

covered with Bardolin should be ventilated according to the

rules of cold roofs ventilated and which is applied on building

use thermal insulation and don’t use steam penetration material.

But there is no need for any extra arrangement with roof which

have enough arrangement

When roof

ventilation is through out extensors, there is need for taking

proper arrangement to form inlet and outlet for the air.

Regulating of air inlet on roof edge should be 4 cm at least,

and should continue along the roof edge. Also providing air

outlet from theback part of the roof is necessary to use the

back ventilation produced from the vertical and slope back of

the roof. We stick singil on these elements by using Bitumineun

boards to supply the external unificated view.

Singil used for

covering back ventilation element or standard.

Elements can be

fixed on covering surface by opening gaps with sharp saw, and

then fixing them with Bardoline nails . ends shall be covered

with singil using bardostick material. To supply the required

amount of ventilation means to creat enough numbers of

ventilation elements.

Ventilation

chimney can be used for discharging air outlets except smoke

chimney and without any penetration of water, and it can be

fixed like ventilation elements. In regions which endanger a lot

of snow ventilation chimney can be used instead of ventilation

element.

4 Back boards and

slope drainage canals:

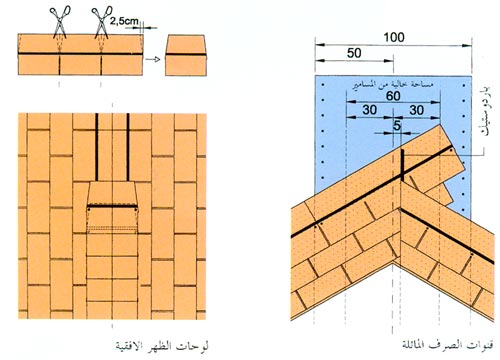

Singil can be cut

into three pieces, and each piece can be fixed on part of back

board if the back board do not need ventilation. On roof which

are covered with traditional type of singil, it is recommended

to use standard back board.

Bituminnem

Bolymer covers reinforced with fibers must be used as aground

for drainage canals. Cover should be sticked by flame machine.

In singil covering it is recommended not to use nails, and it is

better to make use of sticking method

During

application, singil spread on the first face should pass over

the slope drainage path with 30 cm, while singil spread on the

other face should be cut at the conjunction of two faces and

along the drainage canal. Singil should be sticked with

bardostick of the path 30cm left.

5 Finishing of

chimney walls and roof edge:

The structure of

flexible Bardoline singil facilitate the process of forming the

chimney’s finishing. Using Bolymer Bitumin cover rein forced

with fibers as an underground base in these points is useful for

non penetrating water.

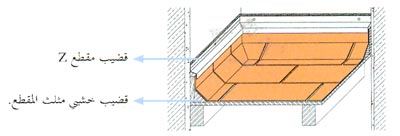

Details of roofs

and walls conjunctions can be solved by a bar section Z . on

roof, edges and walls downs. Moreover Isobaand the Bolymor

binumin tap which is rein Forced with fibers and covered with

aluminum Facilitate solving details as element with wide field

of use.

6 Roof gap:

Ends of roof gap

is designed to be used with Binuminnm singil. The cover of roof

gap is transparent and can be opened and it is also fixed in

many angles. This helps to ventilate the internal side of the

roof and can give it proper enlightenment. The method of

application is the same one applied on ventilation element.

Technical

specification :

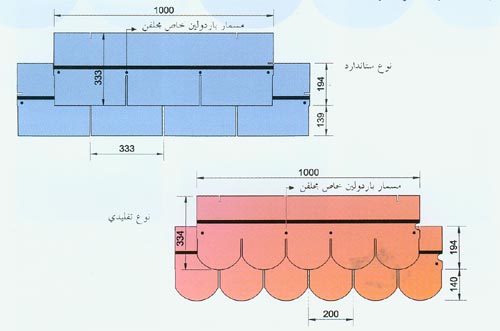

Singil of

Bardoline S, Bardoline and Bardoco are produced in two shapes,

traditional shape and standard one.

Bardoline and

Bardoline S colors are of two approximate degrees of five

colors, while Bardco group of colors have two main colors.

|

BARDOLINE |

Technical

specification |

|

TS EN 544 SINIF 1 4X21 |

standard |

|

125 g/m2 110g/m2 |

Heaviness of glass

fibers |

|

Sticker in hot place

- Sticker in all circumstances |

Type of sticking tap |

|

Traditional

standard |

Kinds |

|

5 colors with tow

degrees |

Colors |

|

334mm |

Traditional width |

|

1000mm |

Traditional length |

|

333mm |

standard

width |

|

1000mm |

standard

length |

|

>800N/5cm

>600N/5cm |

longitudinal

tighten resistance |

|

>600N/5cm

>600N/5cm |

transverse

tighten resistance |

|

>100N |

longitudinal

tearing resistance |

|

>100N |

transverse

tearing resistance |

|

90°C |

temperature

of sloping test |

|

10.4Kg/m2; 31.2kg/paket |

weight Traditional |

|

11.4kg/m2; 33.1kg/paket |

weight

standard

|

|

3.0m2/paket |

Total covering area

Traditional |

|

2.9m2/paket |

Total covering area

standard

|

|

boxes covered with

perforated Bioly Ethelin |

type of packing |

|

21 |

Number of Boards in

each pack |

|

33(=99.0m2) |

Number of packets in

the Balat

( Traditional ) |

|

30(=87.0m2) |

Number of packets in

the Balat

(

standard

) |

|

1030kg |

Weight of the Balat (

Traditional ) |

|

992kg |

Weight of the Balat (

standard

) |